The History of Our Distillation Process

Our History

Medical herbalism has been our interest for many years- and living in Crete, herb collections from the wild has occupied a lot of our time. Crete is blessed with a multitude of wild, remote biotopes, an abundance of aromatic plant populations. We were always roaming the mountains. In 1994 we decided to start to distill essential oils from the locally growing wildcrafted aromatic plants. We started by using an old still made of galvanised copper, from 1924, a real beauty. These traditional stills are used to distill 'moonshine', raki or as it is called on Crete, tsikoudia. In order to somewhat obtain a steam distillation process, we made a hanging sieve to fit in the retort. The still was heated by a wood fire, and many a night we spend beside it . . .

Magical Times

Here we experienced our very first distillations of herbs.

Our first still

A traditional Cretan still from 1924

With this device, we could distill about 50-70 ml of essential oil each time from the higher yielding herbs. A very lengthy process. These were our learning years - the mystery of alchemy, nights and nights of distilling, finding the appropriate techniques, the different cooling flow rates required for each herb, the time distillation should last, learning about the requirements of each herb. For some herbs, we did series of distillations with plant material harvested at different times in their growth cycle, series of different distillation times, series of fresh, semi-dried or dry material. Series of distillations with plant material from different locations and altitudes.

In 1995 we started to study the chemistry, extraction methods, pharmacological and biological activities of essential oils, along with general secondary metabolite production and chemistry here in Crete at the Mediterranean Agronomic Institute of Chania (MAICh). This institute offered a postgraduate diploma course on aromatic and medicinal plants, leading to a MSc degree. Since such a course was innovative, we had the great opportunity to meet and be taught by the foremost scientific capacities, professors from all over the world in the field of natural product science in general, and essential oils in particular. We are forever thankful for the interest some professors showed for our particular private project, and thankful for the many tips and discussions which helped us to construct our future stills and work them correctly. In addition, these studies have broadened and expanded our knowledge enormously.

We then constructed two stainless steel distillery units and a stainless steel cooling coil system according to the newest knowledge regarding this constructions for optimum productivity and purity of the oils obtained. Each unit has a capacity of 600 liter volume, and can hold about 40-70 kilos of dried herbs. Few herbs are distilled by what is called a water distillation, that is the plant material is submerged in water, but most of the herbs require a steam-distillation process. In order to avoid the burning of plant material during the process, the stills are insulated. In the beginning we fired the stills with wood.

What a task to keep the temperature stable during all the hours each herb required!

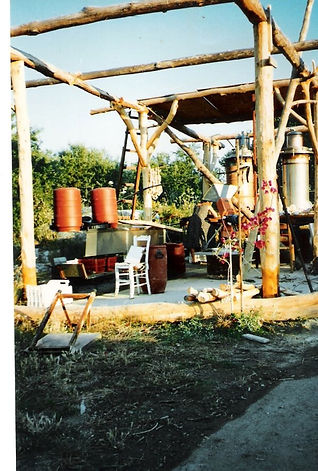

The stills operated by wood fire in the beginning (1995)

We had no roof as yet except for a covering just above the stills

Working in the open, we still had a simple barrel (on the left) to hold our cooling coil. The framework for a covering of the stills and a joining drying place for the herbs was set in 1995

We switched to gas fire later as it was easier to regulate and didn't require constant attention. As regards temperature, we distill at atmospheric pressure and the temperature in the still is as such always below 100°C, following the natural law that ingredients with different boiling points together will boil at a temperature slightly lower than the boiling point of the ingredient with the lowest boiling point. Water has a boiling point of 100°C, whereas many volatile herbal components have boiling points over 200°C. Our oils usually distill between 96°C and 98°C.

To the right you can see the stills, now operated by gas fire. The simple barrel has long ago been replaced with a stainless steel container holding the cooling water (to the left)

We finished the building of the drying place beside the distillery and covered it, and later in 2003 added also a kind of 'sidewing' covering to host a table and friends underneath.

Here you see the drying place to the left and the covering to the right, the 'sidewing'

Our distillery is situated near the village of Modi, province of Chania, surrounded by olivegroves and wild places. In the springtime there are a lot of wild greens around, which we pick for salad, pies and vegetable dishes. Towards the North, we have the view of the sea below, and towards the South we see the white mountains of Crete, which can be snow capped until the beginning of summer . . .

The Southward view from the distillery towards the sea

The snow capped white mountains of Crete visible over the distillery roof to the North an early evening in April

However, even if our production with these units is larger, we still in no way are or will be large producers. This is partly because we want to go on to be a family business, and mainly because we have decided to distill wild plants, and we can not over exploit the natural populations. We only collect plants which are abundantly growing in the mountains and other remote areas, and we take a good deal of care on how we cut, as to give optimal re growth potential to the plants. All our herbs are hand-cut, to avoid to disturb plants, nature, environment and ourselves with noise and destructive energy. We only cut as much, as the plant gives, as much as the plant needs to be clipped in order to live even more vigorously the next year. We weed and clean around the plants, free them for competitors as much as we can. And we experience a kind of unison, a cooperation from these fragrant beings when we are out there with them.

For more than 25 years now, this is the way we work. Not that we haven't been tempted, be it by fame, by greediness or propositions of all kinds. We still collect, distill, bottle and label our oils ourselves. Whatever help we get, is from friends and family, who cherish the way we work, are eager to share moments or hours of contemplation in nature, happy to be part of a transforming practical way to reconnect to being and universe, appreciate the expression of life so fully. Out there with the wild growing plants, each one a proud and happy expression of life eternal, each one a survivor, we appreciate the lifeforce in ourselves and feel gratitude and connectivity with all, everything. These might just be words, but when it is experienced, there is no turning back to commercial thinking.

These are the reasons, why we dedicate our production to people, who think likewise and appreciate the integrity, purity and quality of an essential oil.